Damen Shipyards Group announced the first sale of its innovative Damen Air Cavity System to Amisco. With its ambition to become the world’s most sustainable shipbuilder, Damen has developed DACS to support maritime operators in their efforts to reduce fuel consumption and emissions.

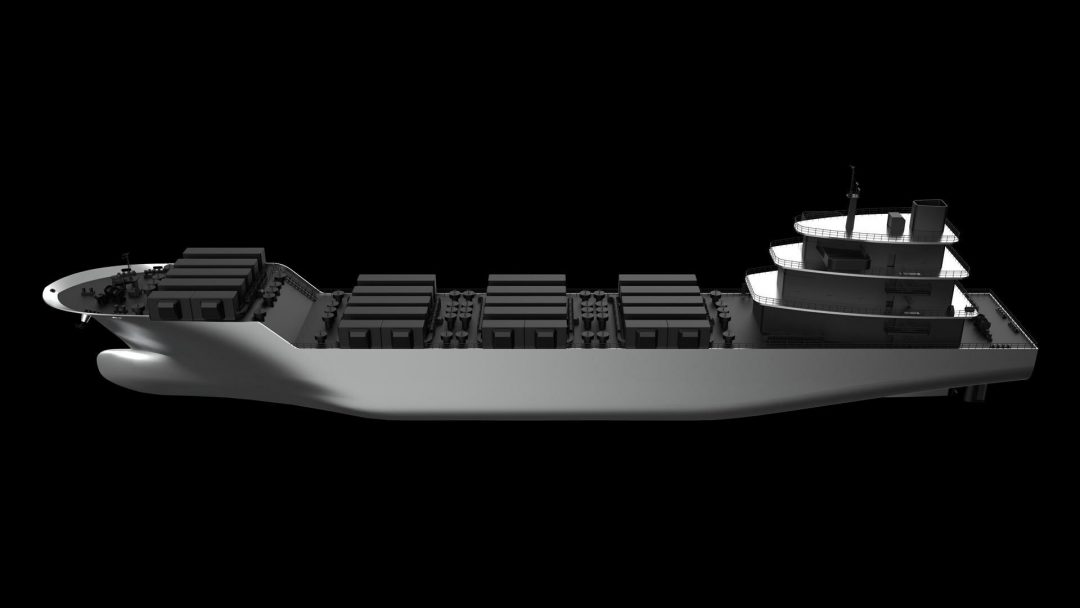

Damen will retrofit the DACS system to Amisco’s cargo vessel Danita in Tallinn, Estonia. DACs is an air lubrication system, borne out of a collaboration between Damen and the Delft University of Technology (TU Delft). It maintains a thin layer of air over the flat bottom of a vessel’s hull, reducing resistance in the water, thereby lowering drag and friction. As a result, the efficiency of the vessel is improved with fuel consumption reduced by up to 15%.

DACS offers vessel operators a straightforward solution, for both newbuild and existing vessels, to comply with regulations such as the Energy Efficiency Existing Ship Index (EEXI) and the Carbon Intensity Indicator (CII) as well as the EU Emission Trading System (ETS).

With DACS installed to Danita, Amisco will achieve the CII rating necessary to continue operating in the Baltic Sea in the face of new, stricter emissions regulations. At the same time, the considerable reduction in fuel consumption allows for a rapid return on investment.

“We are excited to partner with Damen and implement this new technology to reduce our emissions,” said Allan Noor, CEO of Amisco. “The Air Cavity System is a game-changer for us, allowing us to lower the fuel consumption and reduce the CO2 emissions of our current fleet. This marks the initial phase in our continuous commitment to delivering value to our partners through our existing fleet, while collectively minimizing the environmental impact across the entire supply chain.”

Rutger van Dam, Sales Manager at Damen Green Solutions, said, “We are proud to introduce this technology to the market. Reducing emissions is crucial for the future of our industry and DACS is a practical solution that can make a real difference.”

During the verification of the fuel saving results, Damen was supported by the IACS class society, RINA. RINA played a pivotal role in verifying the impressive fuel-saving results achieved by Damen’s technology and thoroughly examined the working principle of the air lubrication system.

With RINA’s expertise and rigorous assessment, Damen received independent validation of the significant fuel savings realized through the implementation of Damen air lubrication system. This collaboration has further reinforced the credibility and reliability of DACS technology.

Pino Spadafora, Marine Commercial Senior Director at RINA, said, “Supporting Damen and Amisco in the application of a technology such as the DACS system is an honour for RINA. Fuel optimization is of paramount importance on existing vessels as much as new builds and cooperation within the industry is the way forward to finding new solutions”.

By involving RINA in the sea trials, Damen demonstrated its commitment to transparency, accountability, and excellence.

Sergei Kravtṡenko, Member of the Board at Tallinn Shipyard, one of BLRT Repair Yards, members of BLRT Grupp, said, “We are delighted that our long-term partner – Estonian-based shipping company Amisco has entrusted us with the installation of DACS system on board their vessel Danita. At BLRT Repair Yards, we take pride in our commitment to excellence and innovation in maritime installations. From expertise and decades of experience, our skilled team was ready to handle the project. This cutting-edge technology will definitely enhance vessel performance and contribute to a greener, more sustainable future. And we are proud to have been a part of the deal”.