Environment

MAN Truck & Bus introduces new MAN Truck Generation

Published

4 years agoon

|

Listen to the story (FreightComms AudioPost)

|

MAN Truck & Bus introduces a completely newly developed truck generation for the first time in 20 years, which is consistently oriented towards the changing requirements of the transportation industry and sets new standards for – among other things – assistance systems, driver orientation and digital networking.

The new truck generation thus represents the development of MAN Truck & Bus from vehicle manufacturer to a provider of intelligent and sustainable transport solutions.

With fuel savings of up to eight percent, the new MAN Truck Generation achieves significant reductions in CO2. The newly developed turn assist helps to prevent serious accidents in urban traffic – four years before the legally prescribed introduction.

The lane change assistant also warns the driver of vehicles in the next lanes. MAN has involved customers and drivers in the development of the new MAN Truck Generation from the beginning, so that their requirements could consistently be made part of the new vehicle.

The new MAN Truck Generation follows in the footsteps of legendary series. The MAN TGA, which was presented in 2000, was formative for truck construction. Not only does the new MAN Truck Generation follow suit, it also brings a new level of comfort, safety, efficiency, reliability, service as well as connectivity and digitalisation.

“Simplifying Business” – the changing transportation industry

Today, the requirements in all areas of the transportation industry are more diverse and complex than ever – forecasts for the future indicate that fundamental transformation of the industry is in “full gear”. This brings great challenges with it – the transport volume in the EU alone is to increase by an additional 40 percent in the next 20 years. At the same time, strict legal regulations are intended to reduce CO2 emissions by 15 percent by 2025 (with an additional reduction by 30 percent by 2030). To make matters worse, there is a growing shortage of drivers. According to current statistics, in Germany there will be a shortage of around 150,000 qualified professional drivers in the next two years alone. Additionally, increasingly comprehensive digitalisation across all logistics processes sets a fast pace for transport companies.

“Our customers expect us to provide them with answers to these questions, and rightly so,” summarises Joachim Drees, the MAN Chairman of the Executive Board. “For their sake, we need to be one step ahead of these changes with all their direct and indirect effects. This is a huge, but at the same time, extremely exciting task – it means that we need to think in different, new dimensions as the manufacturer of our products. We do this with our new truck generation.”

This is why the new MAN truck generation offers everything which customers and drivers have always valued and expected from their MAN vehicles – only even better. It unites tried-and-true virtues with developments which are absolutely future-oriented, in order to take the burden off freight forwarders and drivers and make their daily work easier, despite increasingly complex framework conditions. In doing so, MAN is focussing on four core topics: the driver in their work place, the vehicle’s efficiency and its reliable usability, as well as the strong and competent partnership for customers.

“Excellent driver fit” – the driver is the focus

In order to optimise the work place in the truck and to adjust it to better meet the daily requirements of the driver, their performance and motivation need to be placed at the forefront. After all, the decisive building blocks for a transport company’s economic success are the commitment and satisfaction of drivers. This is why the new MAN truck generation sets standards in terms of user-friendliness, optimum ergonomics, operation which is more intuitive and reliable, networking with digital devices and applications and, last but not least, optimum space, a well-thought-out storage concept and perfect sleeping comfort – all this geared towards needs which were determined based on experience. This is because MAN consistently included the expertise and feedback of drivers and business people throughout the entire development process. Modern assistance systems such as the newly developed turn assist, the traffic jam assistant as well as lane change assist reduce the strain on the driver and ensure increased safety in road traffic.

“Great efficiency & economy”

The Euro 6d engine range, which was introduced back in 2019, realises its full efficiency potential with the new MAN Truck Generation. The perfect interplay of the units with additional, newly developed consumption-reducing driveline and software components provides the future series with a trailblazing level of efficiency. In this way, the new MAN Truck Generation saves up to eight percent of fuel compared to the Euro 6c predecessor version in classic long-haul transport applications, and thus achieves a clear reduction in CO2.

The improved aerodynamics of the new vehicle design also play their part in this reduction. Furthermore, MAN offers additional targeted and practice-oriented training and instruction options with digital applications, in order to support drivers in even more efficient driving methods.

Comprehensive product improvements for components and in the areas of maintenance and service reduce service life costs. Likewise, the new MAN truck generation offers significant payload advantages for weight-sensitive application sectors.

“Optimised uptime” – utmost availability over the entire service life

How “good” a truck is when it is in use largely depends on how efficiently and easily it fulfils its transport task. An important parameter here is reliability. MAN endeavours to make the tried and true even better with the new truck generation, in order to ensure the long-standing product quality (which is repeatedly confirmed in the TÜV report) for the future as well. Take for example the newly developed, simplified, powerful and future-proof electronics architecture, which will significantly improve and expand the functionalities of the trucks.

Additionally, a comprehensively further developed, digitalised maintenance management system reduces operating costs and ensures maximum availability of the new MAN TG vehicles. Fleet management and drivers are supported through numerous digital functionalities and services.

“Strong partner” – competent and personal partnership

At the same time as the new truck generation, MAN is introducing a new consultation and offer system which is entirely oriented towards the needs of the customer. It follows a product logic which is consistently oriented towards the application profile. This allows for a new MAN TGX, TGS, TGM or TGL to be put together into a truck that fits the exact transport task, using comprehensively adjustable and flexible configuration options. This includes individually coordinated services from maintenance, financing and digital services, which make the truck a holistic, integrated transport solution – all this from a single source, with competent personal contact partners. Furthermore, MAN Individual provides a comprehensive portfolio of options to enhance the vehicle and make customer-specific adaptations ex-works.

From customer to product

The claim of the new MAN truck generation of “Simply my Truck” is not just a slogan, but a significant foundation for development – to find out how the ideal work place and living space in a truck should be designed first hand, the MAN developers presented over 700 drivers (including during visits to truck stops and service stations) with different prototype solutions. The feedback from the professionals and their personal wishes went directly into the new series.

Additionally, MAN invited 300 national and international customers from a total of 16 countries to Munich, in order to define the most important requirements for a new vehicle with them in workshops. The developers compared this diverse input with the feedback from the driver interviews, and implemented the resulting core ideas into the numerous innovative features of the new MAN truck generation.

At the same time, MAN is continuously developing the performance of its Sales and After Sales areas further. Based on over 50,000 personal customer surveys a year, new services and products were created which help the customer to optimally utilise their new MAN TGX, TGS, TGM or TGL.

Comprehensive improvements in the production and sales process

The new MAN truck generation does not only entail a new product for MAN; it also involves comprehensive improvements in Production and Sales.

In order for series production of the new MAN truck generation to be ready to go and to be able to simultaneously offer the previous models during the transition phase until the end of 2020, MAN invested around 100 million euros at the Munich site alone, for example. There, up to 500 cabs from the comprehensive range of the new MAN truck generation and the previous TG series are produced a day.

Additional investments amounting to 85 million euros went into the new cab paint shop of the main factory, which can now meet the increased output of cab construction without any problems. It is one of the most state of the art and environmentally friendly plants in Europe and another step on the way to a “green factory”, which MAN is dedicated to achieving.

At the plant in Steyr, Austria where the TGL and TGM series continue to roll off the production line, a new and cutting-edge paint shop was also put into operation. All plastic attachment parts for the entire MAN production network will be exclusively processed there in the future.

Alongside production, MAN also restructured its offer process with the launch of the new truck generation. At the centre of this is a fundamental change in method in product logic which manifests itself in new configuration processes and tools. When creating the offer, the core thought here is to place the individual transport task of the customer at the forefront. This results in a portfolio which is more closely aligned with the market and customers, with a completely integrated range of trucks, After Sales services, finance and digital services. The configuration and offer process is thereby not just much faster, but also provides a high level of flexibility when putting together the perfect tool for the customer’s transport task.

The new MAN Truck Generation – the project in numbers

The introduction of the new MAN Truck Generation is the most ambitious project from the company in 20 years:

- 12,000,000 working hours were spent as part of the project

- 4,000,000 test kilometres driven up to market launch

- 2,800,000 lines of software code

- 167,000 working hours were put into the new vehicle design

- Around 22,000 new item numbers were integrated into all departments

- 3,000 cab colours are available as standard

- 2,100 MAN employees were directly involved in the project

- 8 cab sizes are available for the new MAN Truck Generation

- Up to 8 percent less fuel consumption

- 4 series: MAN TGX, TGS, TGM or TGL

- 1 team: the 36,000 employees at MAN Truck & Bus

You may like

-

MOL joins GCMD as impact partner to accelerate decarbonisation

-

Hapag-Lloyd partners with DB Schenker to decarbonise supply chains

-

EU member states agree to the “FuelEU Maritime” regulation

-

APM Terminal invests in port-equipment electrification pilots

-

HHLA to introduce passify, a digital solution to replace trucker card

-

IAG Cargo to reduce emissions by partnering with Kuehne+Nagel

Environment

MOL joins GCMD as impact partner to accelerate decarbonisation

Published

9 months agoon

August 9, 2023

|

Listen to the story (FreightComms AudioPost)

|

The Global Centre for Maritime Decarbonisation GCMD and MOL announced the signing of a five-year Impact Partnership agreement. On the same day, both parties held a signing ceremony at the GCMD office in Singapore.

Decarbonisation in the maritime industry is a challenge that needs to be achieved through accelerating collaboration and increasing investment by shipping companies, their customers, ports, energy suppliers and public sector actors. As an Impact Partner of GCMD, MOL will utilise its expertise developed over their long history and make various contributions and collaborations through its participation in GCMD’s projects, including providing access to vessels, operating data and evaluation reports so that internal learnings can be shared publicly and used for future trials.

MOL is one of the world’s leaders in the maritime industry and has been leading worldwide discussions on achieving decarbonisation. The carbon budget concept imposes a ceiling to the cumulative amount of greenhouse gas (GHG) that can be emitted globally in order to limit global temperature rise to 1.5 degree Celsius by 2050. Intermediate targets to reduce emissions, in addition to a net-zero target, are necessary. While plans are in place to adopt low or zero emissions vessels in the future, it is important to deploy measures to reduce emissions now. Such measures include the use of low-carbon and transition fuels that are available today, and deploying energy savings devices onboard vessels. MOL will bring its extensive capabilities and experience to bear as it joins GCMD and existing partners to accelerate international shipping’s decarbonisation.

Professor Lynn Loo, CEO of the Global Centre for Maritime Decarbonisation, said: “We are proud to have MOL, one of the leading shipowners in Japan, come onboard as an Impact Partner. We are excited to tap on MOL’s track record in developing technical energy efficiency measures to broaden our perspective as we scope an initiative to help increase industry adoption of measures that can increase fuel efficiency of ships.”

Toshiaki Tanaka, Representative Director, Executive Vice President Executive Officer, and Chief Operating Officer of MOL, said: “We are very pleased to be a partner of one of the most important global coalitions. We will make our biggest effort to contribute and accelerate progress towards the net zero future in maritime industry, together with GCMD and all its partners.”

About the Global Centre for Maritime Decarbonisation

The Global Centre for Maritime Decarbonisation (GCMD) was set up on 1 August 2021 as a non-profit organisation. Our strategic partners include the Maritime and Port Authority of Singapore (MPA), BHP, BW Group, Eastern Pacific Shipping, Foundation Det Norske Veritas, Ocean Network Express, Seatrium, bp, Hapag-Lloyd and NYK. Beyond the strategic partners, GCMD has brought on board 15 partners that engage at the centre level, in addition to more than 80 partners that engage at the project level.

Strategically located in Singapore, the world’s largest bunkering hub and second largest container port, GCMD aims to help the industry eliminate GHG emissions by shaping standards for future fuels, piloting low-carbon solutions in an end-to-end manner under real-world operations conditions, financing first-of-a-kind projects, and fostering collaboration across sectors.

Environment

Hapag-Lloyd partners with DB Schenker to decarbonise supply chains

Published

9 months agoon

August 8, 2023

|

Listen to the story (FreightComms AudioPost)

|

Hapag-Lloyd has entered into a partnership with DB Schenker for the purpose of decarbonising supply chains. Following the launch of “Ship Green” in May, the renowned logistics provider has selected Hapag-Lloyd’s sustainable transport solution as part of its sustainability initiatives.

DB Schenker and Hapag-Lloyd have signed an agreement for emission-reduced container transports with a waste- and residue-based biofuel. By end of 2023, DB Schenker plans to claim approximately 3,000 metric tonnes of carbon dioxide equivalent (CO2e) emissions avoidance. This is based on at least 1,000 tonnes of pure biofuel.

“We are excited about this new partnership with DB Schenker as we share the common goal of making logistics more sustainable. Collaborations like these set a clear signal in the industry and are another example of a step-by-step approach to further decarbonise supply chains”, said Henrik Schilling, Managing Director Global Commercial Development at Hapag-Lloyd.

“I am very pleased that together with Hapag-Lloyd we are setting another example for sustainability in our industry. This partnership further enlarges our global biofuel offer in ocean freight. With this commitment we are one step closer to our goal of becoming carbon-neutral”, said Thorsten Meincke, Global Board Member for Air & Ocean Freight at DB Schenker.

Hapag-Lloyd has launched the Ship Green product to offer its customers emission-reduced ocean transports. Based on biofuel, customers of Hapag-Lloyd can add Ship Green as an additional service to their existing bookings – thereby avoiding CO2e emissions. Using the so-called “Book & Claim” chain of custody, Hapag-Lloyd can attribute avoided emissions to all ocean-leg transports, regardless of the vessel and route used. Ship Green is available for all shipments containing standard, hardtop or tank equipment. By offering Ship Green, Hapag-Lloyd is continuing along its path towards achieving climate-neutral fleet operations by 2045.

Environment

EU member states agree to the “FuelEU Maritime” regulation

Published

9 months agoon

July 27, 2023

|

Listen to the story (FreightComms AudioPost)

|

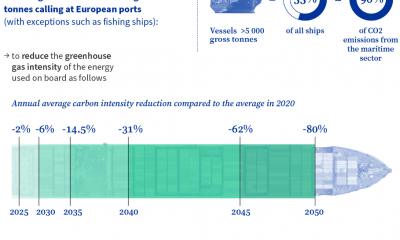

EU Member States cleared the way to bring sustainable renewable fuels into maritime transport. They approved the “FuelEU Maritime” regulation. The EU Parliament had also voted in favour of the agreement reached in the trilogue procedure.

The new requirements will apply to ships with a gross tonnage of more than 5,000 entering, leaving or staying in ports in the territory of an EU Member State. In addition, shore-side electricity will be mandatory for container and passenger ships from 2030. The use of synthetic fuels from renewable energies will be specifically promoted for shipping.

Federal Minister of Transport Dr Volker Wissing:

After we were recently able to achieve a breakthrough for maritime climate protection at UN level, we are now pushing the actual transformation towards climate-neutral shipping at European level with the “FuelEU Maritime” initiative. The draft regulation is open to technology and takes into account the special competitive conditions in the maritime transport sector. The main objective is to increase the demand for renewable and low-carbon fuels and their consistent use, thereby decisively reducing greenhouse gas emissions in maritime transport. The initiative is thus expected to play a fundamental role in the implementation of the European Climate Change Act for shipping.

Federal Environment Minister Steffi Lemke:

Today the EU has set a decisive course for more climate protection and the use of renewable fuels in maritime transport. Shipping companies will continue to rely on fuels in the future, because electric drives are not yet an option for long-distance transport. In maritime transport, e-fuels from renewable energies are therefore a sensible climate-friendly alternative. With the new requirements, the EU is giving manufacturers and shipping companies the necessary planning security, driving forward the development of modern technologies and making renewable fuels for maritime transport ready for the market. But there are also shadows: The fact that fuels from fossil sources and nuclear energy are also permitted as a compliance option is regrettable. The German Federal Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection (BMUV) will continue to advocate the use of predominantly synthetic fuels from renewable energy sources in order to make maritime transport climate neutral.

FuelEU Maritime lays down uniform EU-wide rules for limiting the greenhouse gas intensity of the energy used on board a ship, and thus above all the fuels. The regulation from the Fit for 55 package stipulates that shipping in the EU must reduce its emissions by 2 percent from 2025, 6 percent from 2030, 14.5 percent from 2035, 31 percent from 2040, 62 percent from 2045 and 80 percent from 2050. The GHG intensity reduction targets are set against the 2020 average GHG intensity of energy consumed on board ships. The greenhouse gas emissions of all fuels are assessed on the basis of a life cycle assessment (so-called well-to-wake (WtW) approach that includes the greenhouse gases carbon dioxide, methane and nitrous oxide). All fuels are permitted as a compliance option; the legislative initiative is thus technology-neutral.

The use of synthetic fuels is encouraged by a special mechanism: if the share of synthetic fuels from renewable energy sources (so-called “renewable fuels of non-biological origin, RFNBO) in the fuel mix does not exceed one percent in 2031, a mandatory minimum quota of two percent for these RFNBO fuels will automatically come into force from 2034. Beyond the use of alternative fuels, the FuelEU Maritime Regulation obliges container and passenger ships in ports in the territory of a Member State to use shore-side electricity or alternatively zero-emission technologies for on-board energy supply.

This Regulation shall enter into force on the twentieth day following that of its publication in the Official Journal of the European Union. It shall apply from 1 January 2025, with the exception of certain Articles which shall apply from 31 August 2024.

Search

The Port of Valencia begins electrification of its docks

Ryder establishes Baton, a Ryder Technology Lab, based in Silicon Valley